Hot rolled and cold drawn tubing are made by two different processes. Obviously, there are many differences between them. Wanzhi Steel offers you a full range of hot rolled and cold drawn tubes in all sizes. Whether you are using them for fluid transfer, parts manufacturing, or hydraulic equipment, they are a great choice. We are at your service 24/7. If you have plans to purchase them, feel free to contact us for more details.

The Difference Between Cold Drawn and Hot Rolled Tubes

1. Processing Method

From the processing point of view, hot-rolled tubes are made by hot processing, while cold-drawn tubes are made by cold processing. Hot rolling is rolling at a temperature higher than the recrystallization temperature, and cold rolling is rolling at a temperature lower than the recrystallization temperature. Therefore, they are processed differently from each other.

2. Application

Hot rolled steel pipe is used for fluid transportation, mechanical structures, and other occasions with low dimensional requirements. And cold rolled steel pipe is generally used for equipment, hydraulic systems, pneumatic, and other demanding occasions.

3. Price

The manufacturing process of cold drawn tubes is more complex than that of hot rolled tubes. Cold drawn tubes are rolled several times, while hot-rolled tubes are much simpler to manufacture. Therefore, the price of cold-drawn tubes is relatively high. According to the price in the market, the price of hot-rolled steel pipe is about 30-75 USD per ton lower than that of cold-drawn pipe.

4. Dimension

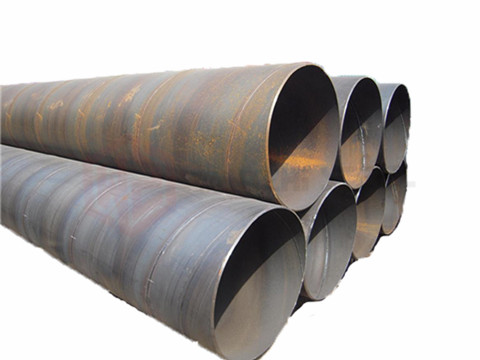

Hot rolled steel pipes are usually of large diameter, while cold rolled steel pipes are usually of small diameter. The former usually has an outside diameter greater than 32mm and a wall thickness of 2.5 to 75mm, while the latter can reach a diameter of 6mm and a wall thickness of 0.25mm. you can choose according to the specific size required for your project.

5. Appearance

The surface of cold rolled pipe is bright and the size of the caliber is smaller than that of hot-rolled seamless steel pipe. The caliber of hot rolled steel pipe is larger than that of cold rolled seamless steel pipe, and the surface has obvious scales or red rust. Generally speaking, the surface finish of cold rolled pipe is much better than that of hot-rolled pipe.

Choose Cold Drawn or Hot Rolled Tube?

If you are struggling to choose cold drawn steel pipe or hot rolled steel pipe. Wanzhi Steel, as a leading steel pipe manufacturer, would like to offer you some tips.

1. Choose According to Actual Needs

If your project does not require high dimensional requirements, you can choose hot rolled steel tubes. On the contrary, if the requirement for precision is high, then cold drawn steel tubes will be your best choice.

2. Choose Based on Budget

Obviously, the price of cold-drawn tubes is higher than that of hot-rolled tubes. If you plan for a lower budget, you can choose hot rolled pipe to save your money. But remember don’t be greedy for a small price to avoid being cheated.

3. Consult with Professionals

If you still can’t decide, you can consult with a professional, such as Wanzhi Steel. As a steel pipe manufacturer with 17 years of experience in the industry, we are qualified to provide you with the right solution for your project.

Conclusion

Wanzhi Steel has been supplying hot rolled and cold drawn tubing for decades. We have our factory and advanced production line. We can supply you with large quantities of steel products. No matter what industry you intend to use it in, you will find the right steel pipe with us, such as round, square and rectangular pipes. In addition, we offer discounts for bulk orders. Contact us now for detailed information on hot rolled tubes, cold drawn tubes, and other tubes.