Welded Steel Tube

Welded steel tube is a lower-cost option than seamless tube. It is commonly used in low-pressure fluid conveying, steel structure, manufacturing materials in automotive industry, etc. Wanzhi Steel has a wide range of welded tubes to choose from, including ERW (electric resistance welded) pipe, SAW (submerged arc welded), longitudinal and spiral welded pipes, etc. Also, you can choose galvanized finish or stainless welded tubes with different shapes (round, square, rectangular, etc).

Welded Steel Pipe Specifications

| Item | Longitudinal Welded Tube | Spiral Welded Tube |

| Outer Diameter | 10 mm-200mm | 20 mm-600 mm |

| Wall Thickness | 0.5 mm-10mm | 1 mm-20 mm |

| Length | 6m/12m | 6m/12m |

Applications of Welded Steel Pipe

Welded steel tube is mainly used to transport low-pressure fluid, for example,

1. For liquid and gas transportation, such as water, petroleum, gas, sewage, etc.

2. Construction and infrastructure use, like structural columns and beams, scaffoldings, electrical and light poles, fencing, furniture, etc.

3. Agriculture, such as greenhouses, agricultural or mechanical equipment, etc.

4. Automotive and aerospace industry, making body frames, supporting structures, etc.

5. Energy, for instance, solar brackets and bases, solar racking, power plants, etc.

Types of Steel Welded Pipes

1. According to Welding Seam

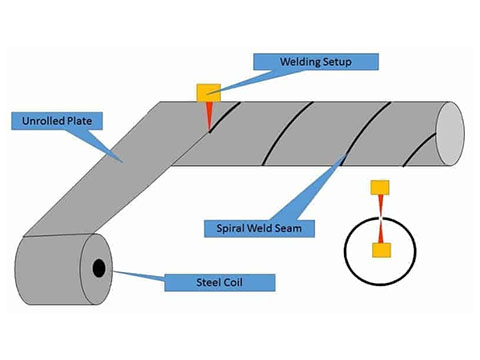

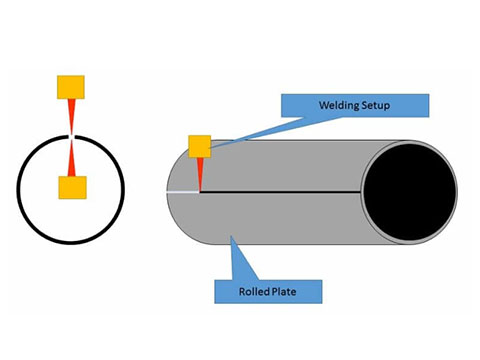

Welded steel pipes can divide into straight seam welded pipes and spiral welded pipes.

2. According to the Use

Seamless steel pipe is further divided into general welded pipe, galvanized welded pipe, oxygen is blown welded pipe, electric wire casing, metric welded pipe, roller pipe, deep well pump pipe, automotive pipe, transformer pipe, electrically welded thin-walled pipe, electrically welded shaped pipe and spiral welded pipe by application.

3. According to Shape

According to the end shape, it can divide into round welded pipe, square, rectangular, and special-shaped welded pipe.

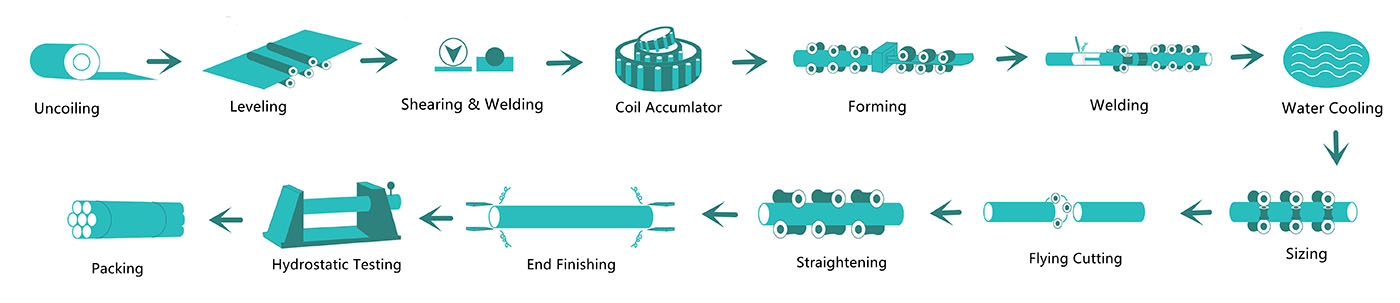

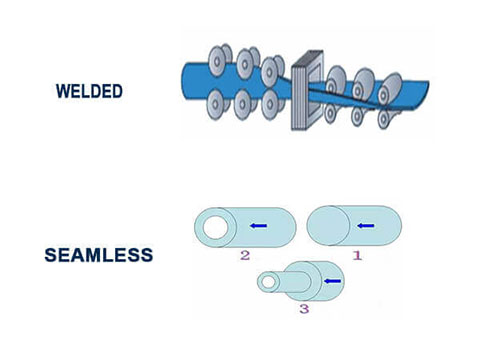

How Is Welded Steel Tube Made?

Welded pipe is made out of flat steel plates, known as skelp, that are formed, bent, and prepared for welding. After pre-treatment, it will be welded into a tubular product with a weld. The general process is shown below.

Raw material unrolling → flattening (leveling) → terminal shearing and welding → live sleeve → forming → welding → cooling → sizing and straightening → end finishing→ hydrostatic inspection → packaging.

Below is a working flow for your reference.

Differences Between Longitudinal and Spiral Welded Pipes

1. Processing Methods

Longitudinal welded pipe consists of bending a steel plate of a certain width into a tube and then welding it into shape. The equipment is simpler and the productivity is higher. And spiral welded pipe rolls a certain width of steel plate into a tube shape. The equipment is more complicated. In addition, the weld seam of spiral welded pipe is 30%-100% longer than that of straight welded pipe, so the productivity of spiral welded pipe is relatively low.

2. Welding Process

The production process of longitudinally welded pipes is relatively simple. The main production processes it uses are high-frequency welded longitudinal welded pipe and submerged arc welded longitudinal welded pipe. While spiral welded pipes use submerged arc welding.

3. Strength

The strength of spiral welded pipe is stronger than longitudinal welded pipe.

4. Pressure-bearing

Welded steel pipes have a high production efficiency. This means the delivery time of your order will also reduce, thus saving you time costs.

5. Sizes

Smaller diameter welded pipes mostly use straight seam welding, and large diameter welded pipes mostly use spiral welding.

Why Choose Welded Steel Tubing?

1. Easy to Produce

Welded steel pipes have a high production efficiency. This means the delivery time of your order will also reduce, thus saving you time costs.

2. Low Cost

The cost of welded steel pipe is lower than seamless steel pipe. It is an excellent choice for general-purpose tubing in a variety of industries.

3. Easy to Install

Welded pipe joints are light in weight. Because welding can basically adopt the form of butt joint, the structure is simple. It can save your time and effort.

Welded Steel Pipe Price

The price of welded steel pipes is USD 500~1000 per ton. But prices are often influenced by many factors and can change from day to day. We have our own factory and a professional multilingual team at your service. Please contact us for a free quote.

Get A Quote from Welded Steel Tube Manufacturers

Wanzhi Steel is one of the top qualified steel tube manufacturers in China. We have different types of pipes and tubes with a wide range of sizes for sale, including seamless tubes and welded tubes, galvanized tubes, as well as stainless steel tubes. Welcome to contact us for a factory direct sale price.

Conclusion

Wanzhi Steel is committed to providing welded steel pipes for many applications in any industry. Our products are manufactured in strict accordance with national standards and have standard production lines. In addition, We can also customize different lengths, wall thicknesses, strengths, etc. If you are looking for high quality and reasonably priced welded steel pipes, please contact us now.