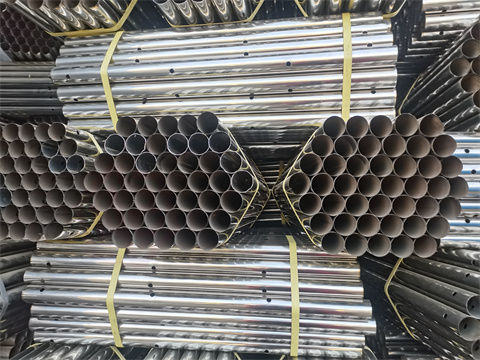

Seamless Stainless Steel Tube

Seamless stainless steel tube from Wanzhi Steel comes in a wide range of sizes and grades, including 304, 304L, 316, 316 L and more. The most common sizes range from 1/4” to 12”, and we also offer custom solution to better meet your project needs. Due to their corrosion resistance and good machinability, stainless steel seamless tubes are used in a wide range of industries, such as power distribution, automotive industry, chemical and petrochemical applications, oil and gas pipelines, etc. Welcome to contact us for more details!

Seamless Stainless Steel Tubes for Sale

| Product Item | Seamless Stainless Steel Tubes |

| Outer Diameter | 1/8” to 24” (6mm to 530 mm) |

| Grades | 304, 304L, 316, 316L, 316L, 317L, 321 , etc. |

| Length | 6m or 12 m or custom length |

| Wall Thickness | 0.8-34 mm or as per customer request |

| Services | Bending, cutting, polishing, punching, etc. |

| Section shape | Round, square, rectangular |

| Finish | Annealed, polished |

| Sample | Available |

| Package | Standard seaworthy package |

Advantages of Stainless Steel Seamless Pipe

1. Excellent corrosion resistance

2. Highstress and heat resistance

3. Smooth surface and attractive appearance

4. High ductility and good machinability

5. Low maintenance

Applications of Seamless Stainless Steel Tube

Stainless steel tubes can withstand corrosive or chemical environments and high temperatures. It means they are safe for long-term use. You can find SS tubes in automobiles, food processing equipment, water treatment facilities, oil and gas processing, and other industries.

1. Conveying pipelinefor fluid and gas such as water, drainage, oil, natural gas, etc.

2. Tubes for heat exchangers,boilers, condensers,

3. Construction uses, such as stair handrails, guardrails, windowsand gates, etc.

4. Foodprocessing or sanitary uses, medical and petroleum industries, etc.

SS 304 Seamless Pipe VS SS 316 Seamless Pipe

There are more than 60 grades of stainless steel. SS 304 seamless pipe and SS 316 seamless pipe are the most common types. Both of them are available in Wanzhi Steel. Next, let’s see what is the difference between them.

1. Different Components

SS 304 contains 18% chromium and 8% nickel, while SS 316 is made of 16% chromium, 10% nickel and 2% molybdenum.

2. Different Prices

Because of the added molybdenum and nickel elements in 316, SS 316 seamless pipe is more expensive than SS 304 seamless pipe. But in the long run, SS 316 seamless pipe is more cost-effective because it is more resistant to corrosion.

3. Different Features

SS 304 seamless pipe features good processing performance and high toughness. SS 316 seamless pipe has superior corrosion resistance and high-temperature resistance.

4. Different Applications

SS 304 seamless pipe is widely used in water piping, indoor enclosures, kitchen equipment, decorative trim, etc. SS 316 seamless pipe is ideal for chloride and acidic environments, such as petroleum, chemical piping and equipment, marine equipment, commercial kitchen appliances, etc.

How to Make Stainless Steel Seamless Pipe?

The following is the manufacturing process of stainless steel seamless tubes for your reference.

1. Hot Rolled Stainless Steel Seamless Pipe

Round pipe billet → heating → perforation → three-roll slant rolling, continuous rolling or extrusion → deburring → sizing (or reducing) → cooling → straightening → hydrostatic test (or flaw detection) → marking → storage

2. Cold-drawn Stainless Steel Seamless Steel Pipe

Round pipe billet → heating → piercing → beating → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → billet → heat treatment → straightening → hydrostatic test (flaw detection) → marking → storage

SS Seamless Pipe Manufacturer – Wanzhi Steel

Wanzhi Steel is a leading steel tubing supplier, which offers quality products and full service. Below is what we can provide for our clients.

1. Full Range of Steel Tubes

Wanzhi Steel offers steel tubes and pipes in different sizes, shapes, materials, and grades. Except for SS tubes, we also have galvanized steel tubes and carbon steel tubes for sale. If you have special requirements, you can ask us for a custom solution.

2. Quality Guarantee

All Wanzhi products are strictly inspected before delivery. You can come to check your products on-site or by video chat. If you have any questions when receiving goods, please feel free to contact us. We will get back to you in 12 hours.

3. Value-added Service

Wanzhi Steel offers value-added services, such as cutting into custom length, bending, polishing, punching, etc. If you have special requirements, please inform us.

Request SS Seamless Tube Price

Seamless stainless steel pipe can withstand high temperature, high strength, and corrosive environments. It offers good strength and hardness, great ductility, and an attractive appearance compared to carbon steel tubes. It is a better choice for long-term uses. Wanzhi Steel is one of leading global manufacturers of steel tubes. We offer a wide range of welded and seamless stainless steel tubes in different sizes, wall thicknesses, shapes and grades. Welcome to contact us for more details!