Seamless Steel Tube

Seamless steel tube is mainly used as fluid pipelines, such as the transportation of oil, natural gas, water, etc. Due to its lightweight and affordability, it is also widely used as structural and mechanical parts, such as oil drill pipe, steel scaffolding. Wanzhi Steel offers seamless steel pipes with different designs, shapes, sizes, and materials. Welcome to contact us for more details!

Seamless Pipe for Sale

| Item | Cold Drawn Pipe | Hot Rolled Tube |

| Wall Thickness | 2.5 mm-12 mm | 2.5 mm-75 mm |

| Outer Diameter | 5 mm-200 mm | 32 mm-630mm |

Common Applications of Seamless Steel Pipe

Seamless steel pipe is a great solution for uses under high temperatures, high pressure, or corrosive conditions, such as:

1. Gas or liquid transportation pipeline

2. Pipeline fittings, such as the loaded parts, rear axle tubes of cars and tractors

3. Chemical and petrochemical industry, such as oil drill pipe

4. Tubes for heat exchangers and condensers, etc.

Advantages of Seamless Steel Tubes

1. Light in Weight

As structural steel materials, steel tube is lightweight. It is weight is only 1/5 of a solid steel bar of the same size. It also makes steel tubes more affordable.

2. High Pressure Resistance

Compared to the welded steel tubes, seamless tubing has a higher ability to withstand pressure. It also has excellent resistance to corrosion, acid, alkali, and salt. The service life will be more than 15 years.

3. High Strength Under Loading

The tensile strength of a seamless steel tube is more than 8-10 times that of ordinary steel. Its elasticity is also better than other steel. More than that, it is easy to process for other uses.

4. Uniformity of Shape

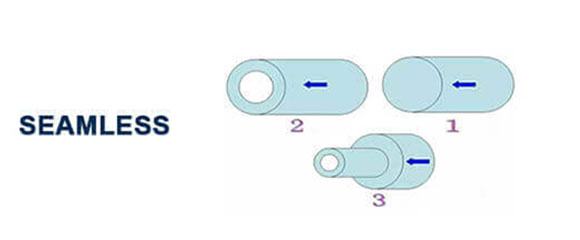

There is no welded seam on seamless steel pipes, which makes it surface smooth. More than that, seamless tubing is a continuous extrusion of the alloy, which means that it will have the same cross section that you can count on.

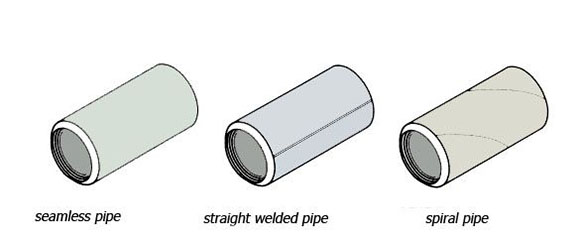

Types of Seamless Steel Tube

1. According to Section Shape

Seamless steel pipes can be divided into seamless square tubing, rectangular and round steel tubes. Seamless square rectangular pipes are suitable for building structures, while seamless round pipes are generally used for the transportation of liquid, such as oil, water, gas, etc.

2. According to Material

Seamless steel tubing is classified into seamless stainless steel (SS) tubing, carbon steel seamless pipes, and galvanized seamless pipes. The material matters their service life and price. You can choose according to the use environment and your budget. Also, you can contact us for some professional tips.

3. According to Production Method

The common types of seamless tubes include hot rolled seamless pipes (HRS), cold-rolled seamless pipes, cold drawn seamless pipes (CDS), extrusion pipes, etc. There are some differences between them. Please keep reading for more details.

Seamless Steel Tube Manufacturing Process

The common seamless steel pipe manufacturing process includes cold drawing and hot rolling process. The tubes are called cold drawn pipes and hot-rolled pipes. Let’s review the making process:

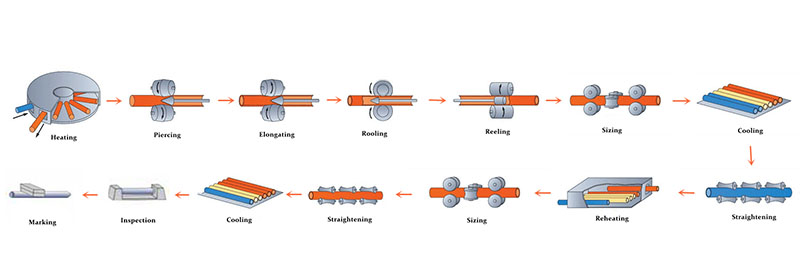

HRS Tubing Making Process

Tube billets→ Heating → Punching → Tube rolling → Reheating → Sizing → Cooling → Straightening → Hydrostatic test (crack detection) → Marking → Stock for sale

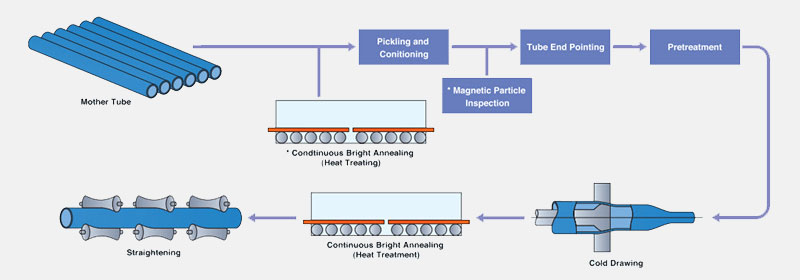

CDS Tubing Making Process

Cold drawn seamless pipe uses hot-rolled steel coil as material. Below is the process:

Tube billets → Heating → Punching → Hollow heading → Annealing → pickling → Oiling → Cold drawing (cold rolling) → Billet tube → Heating → Straightening → Hydraulic test (crack detection) → Marking → Stock for sale

You can also find some videos from Wanzhi Steel Youtube Channel.

Differences Between CDS and HRS Tubes

1. Dimensional Accuracy

The dimensional accuracy of CDS pipes is higher than that of HRS pipes. It can greatly save machining hours, improve material utilization, and at the same time help improve product quality.

2. Appearance

The surface of cold-drawn seamless steel pipe is shiny, while the surface of hot-rolled seamless steel pipe has obvious oxidation scales or red rust.

3. Size

The caliber of cold drawn seamless pipe is usually smaller than that of hot-rolled seamless steel pipe. The diameter of the cold-drawn seamless tube can be up to 6mm and the wall thickness can be up to 0.25mm. The outer diameter of the hot rolled seamless steel pipe is generally greater than 32 mm and the wall thickness is 2.5-75mm.

4. Price

The price of CDS pipe will be 150-300 US dollars higher per ton than that of HRS steel pipe.

Request A Quote for Seamless Steel Tube

Wanzhi Steel offers a large variety of seamless steel tubes and pipes to meet different application needs. Our professional staff will help you to find the most suitable tubing to fit your specific requirements. Besides, we have our own factory and plurilingual teams to serve you to save your time and money. Talk to us now to find the best tubing for your projects or get a free price quote here.