Galvanized Round Tubing

Galvanized round tubing is available in sizes from 1/2″ to 12″ diameters. It is more durable than carbon steel tubes but more cost-effective than stainless tubes. Besides, round tubing has one continuous surface with no edges, which makes it more resistant to flexing and torsional twisting under weight and pressure. It is commonly used for transporting fluid, such as oil, water, gas, etc. Wanzhi Steel also customizes a wide range of tubes to better meet special projects. Welcome to contact us for more details!

Galvanized Steel Round Tubing Sizes

| Products | Galvanized Round Tubing |

| Material | Carbon steel |

| Shape | Round |

| Surface | Hot-dip galvanizing |

| Size | 1/2 – 12 inch |

| Wall Thickness | 0.5 – 10 mm |

| Length | 6 m, 12 m, or as required |

| Zinc Coating | 30 g – 275 g/m2 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Free Sample | Available |

| Packing | Standard packaging or as required |

Benefits of Galvanized Round Tubing

1. Excellent corrosion resistance & Long service life

2. Lower cost than stainless steel tubes

3. Low maintenance requirements

How to Calculate the Weight of Galvanized Round Tubing?

You can estimate the theoretical weight of your galvanized round tubing with the following formula:

(Outer Diameter (mm) – Wall Thickness) * Thickness(mm) * Length(m) * 0.02466 * 1.0599= (kg/pcs)

For example, if your galvanized steel round tube is 21.3 mm in external diameter, 2.8 mm in thickness, and 6 m in length, the weight of each piece will be ((21.3-2.8)*2.8*6*0.02466*1.0599 ≈8.123 kg/pcs ). If you order 3000 pieces, the total weight is about 24 tons. Then it requires a 20 GP container for shipping. Except for quality products, we will also offer professional shipping tips and other value-added services. Contact us for more details!

Applications of Galvanized Round Pipes

The lightweight and corrosion-resistant material allows its use in many outdoor installments. Below are the detailed applications of the galvanized round tube.

1. Galvanized round tubings are used for pipelines, water, gas pipes, cooler, coal distillate oil exchanger pipe, trestle pipe piles, etc.

2. Galvanized steel round tubings suitable for the oil industry, especially in offshore oil fields, oil heaters and condensation of chemical cooking equipment, etc.

3. GI round pipes apply to steel structure engineering, trestle pipe pile, support pipe for mine tunnel, etc.

4. Galvanised round tubes are used for machinery manufacturing and chassis, etc.

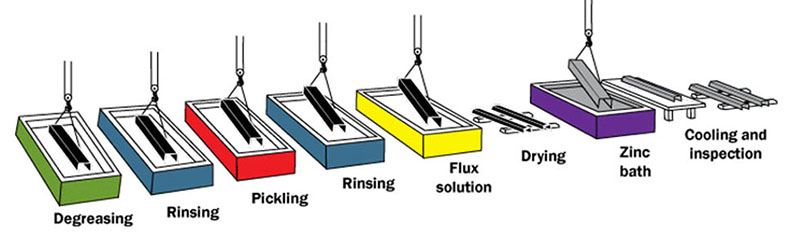

Galvanized Round Tubing Making Process

Meaning of Galvanization

Galvanization is the coating of zinc on the surface of base metal to form a barrier between the steel and the atmosphere. This layer of zinc will serve as an aesthetic, rust-proof, etc. There are two galvanizing methods:

Electro-galvanizing: Using an electrolytic solution to energize and galvanize the surface of the workpiece by ion exchange.

Hot-dip galvanizing: It is the process of coating steel tubing with zinc by immersing the tube in a bath of molten zinc at a temperature of around 450 °C.

Generally speaking, the hot-dip galvanizing process is more commonly used in making tubes. Hot-dip galvanized tubes have better corrosion resistance. So it is very versatile in many applications.

Production Process

Black tube→Alkaline washing→Water washing→Pickling→Water rinsing→Soaking agent→Drying→Hot dip galvanizing→Outside blowing→Internal blowing→Air cooling→Water cooling→Passivation →Water rinsing→Drying→Warehousing

1. Alkaline washing: remove the oil on the surface of the steel pipe.

2. Pickling: remove the oxide scale on the surface of the steel pipe.

3. Water rinsing: remove residual acid and iron salts attached to the surface of the steel pipe.

4. Soaking agent: remove all impurities on the surface of the steel pipe, and ensure that the steel pipe is in clean contact with the zinc liquid to form a good coating.

5. Drying: prevent explosion when a steel pipe is immersed in a zinc pot.

6. Hot Dip Galvanizing: the whole steel tube is soaked in a zinc bath so that the surface of the steel tube is evenly coated with zinc.

7. Outside Blowing & Internal Blowing: blow away the excess zinc liquid of the steel pipe, to obtain a smooth and clean appearance.

8. Water cooling: reduce the temperature of the round galvanized pipe, the temperature of the water cooling tank is controlled at 80℃.

9. Passivation: the surface of the galvanized pipe is passivated by spraying and blowing the finished pipe with passivation liquid.

10. Water Rinsing: wash off the excess passivation liquid.

11. Drying: the galvanized round pipes pass through a drying rack with steam heating pipes, and are packaged after being dried.

Will Galvanized Round Steel Pipes Be Welded?

Galvanized round tubes are weldable. They are welded no differently than ordinary carbon steel pipes. However, they are susceptible to cracks, porosity, and slagging when welded due to the presence of the galvanized layer.

Precautions for Welding

1. The weld must be polished before welding. The galvanized layer at the welding position must be polished off, otherwise, bubbles, sand holes, false welds, etc. will appear.

2. To reduce the penetration of zinc into the weld, the galvanized layer in the recess can be removed before welding.

3. Galvanized steel pipes with a diameter of less than or equal to 100mm should be connected by a thread.

4. Galvanized steel pipe with a pipe diameter greater than 100mm should be connected by flanges or tube fittings. Galvanized steel pipe and flange welding should be galvanized twice.

Measures to Ensure the Quality of Welding

1. Control of welding consumables: ensure that the welding consumables purchased are from regular channels, with quality assurance certificates and certificates of conformity, and meet the process requirements.

2. Welding machine: The welding machine is the machine to apply to weld. It must ensure reliable performance and meet the needs of the process.

3. Welding environment control: to ensure that the temperature, humidity, and wind speed when welding is in line with the process requirements. No welding when no conditions.

4. Quality inspection: pre-weld bevel inspection before welding and appearance quality inspection after welding.

Should Galvanized Round Tubing Be Painted With Anti-Trust Paint?

After the round steel pipe is galvanized, the surface is covered with a layer of zinc coating. The thin and dense zinc protective layer can protect the steel sheet from further oxidation. That’s why the galvanized steel tube is durable to use. Generally, the service life of GI tubing is 30+ years. You may wonder should the galvanized tube be painted with another anti-rust paint. The paint layer can also protect the base metal. Also, it will make the tubing more beautiful. But it will increase the cost. Wanzhi Steel suggests that to be painted or not should depend on the use environment, budget, and expected service life. For example, you can paint the tubes as you like for aesthetic purposes if you have enough budget.

What Is The Life Expectancy of Galvanized Round Tubing?

The galvanized round pipe is used in fabrication, construction, numerous applications, and maintenance due to its long service life. But in different conditions the lifetime of use is different.

Generally speaking, 10-15 years in the heavy industrial district, 25-30 years in the city, 50-60 years in the ocean environment, and over 100 years in the suburbs.

However, GI round pipes are well-built, well-installed, and well-maintained and can easily exceed the typical lifespan.

How to Get A Quote for Galvanized Round Pipes

The price of galvanized round pipe varies from day to day. If you would like to know its latest price, please let us know your specific requirements.

1. Clarify Specifications

Tell us the exact specifications you need, including steel grade, material, size, etc. If you don’t know, tell us the purpose of your use and the environment in which it will be used. We will provide a suggestion.

2. How Much You Need

You need to tell us how much galvanized round pipe you are ready to order. The quantity will directly affect the price. In addition, we offer discounts for large orders.

3. Other Aspects

Where is your destination port? Do you need other services, such as cutting, polishing, etc.? These details will help us to provide you with an accurate quote as soon as possible.

Frequently Asked Questions

1. Can You Meet Large Volume Orders?

Wanzhi Steel has its own factory, located in Hebei Province, China. We can meet large volume orders. If you want to order galvanized round pipes in large quantities, we can also provide you with a factory selling price.

2. Can the Size of the Product be Customized?

Our products are customizable. Please let us know if you need this.

3. How Can I Get Your Quote As Soon As Possible?

Our emails and faxes will be checked within 24 hours. After receiving your quote request, we will get back to you within 12 hours.

4. Can You Provide Samples?

We provide free small samples. But the shipping cost will be paid by the customer.

Conclusion

Galvanized round tubing is fully protected from rust and corrosion. So it has strong corrosion resistance and long service life. But it requires a lower cost than stainless steel pipe. Besides, it is easy to cut, weld, rivet, drill, and screw for different uses. Wanzhi Steel provides tubing solutions for all of your application needs, with different sizes, materials, and shapes. In addition, we also offer full service from pre-sales consulting to after-sales service. Welcome to contact us for more details.